Stainless steel pipe connections require specific techniques to ensure durability and performance. Poor installation can lead to leakage or inefficiency.

Stainless steel pipes are joined using welding, mechanical fittings, or threading methods, ensuring a reliable seal. Proper techniques vary by application, material, and size.

Choosing the right method ensures longevity and efficiency. Keep reading to learn how to select the best technique for your needs.

How are stainless steel pipes connected?

Poor connections[^1] in stainless steel pipes can cause costly repairs. Proper techniques can save time and money.

Stainless steel pipes[^2] can be connected using welding, mechanical couplings, or threaded fittings. Each method suits specific requirements and applications.

Methods for Connecting Stainless Steel Pipes

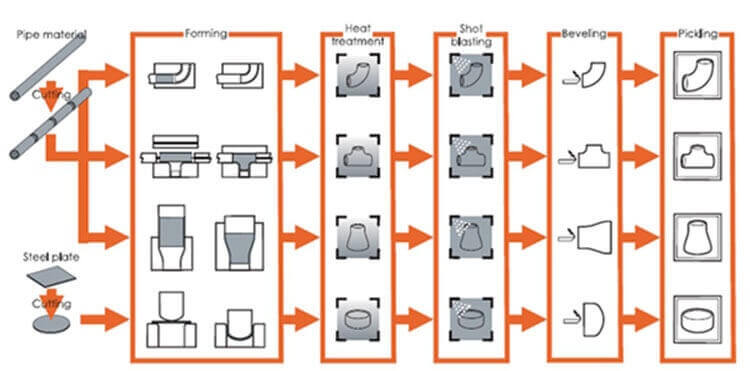

Welding

Welding[^3] involves melting and fusing metals, creating a seamless and durable bond. This method is ideal for industrial and high-pressure applications.

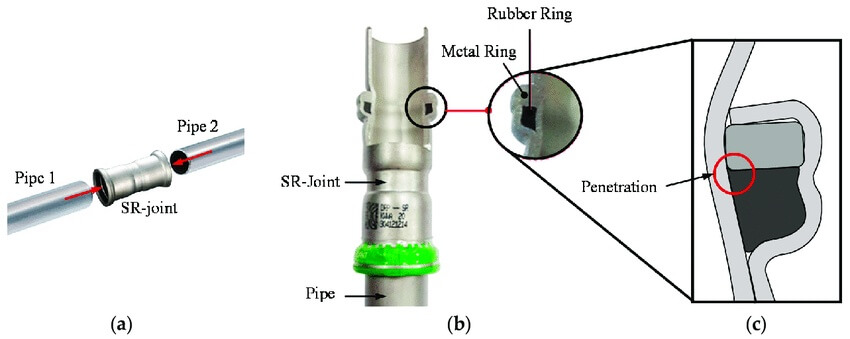

Mechanical Fittings

Mechanical fittings[^4], such as flanges or compression fittings, allow for disassembly and reassembly, making them versatile for maintenance.

| Method | Best for[^5] | Drawbacks |

|---|---|---|

| Welding[^3] | Permanent, high-pressure uses | Requires skilled labor |

| Mechanical fittings[^4] | Temporary or adjustable setups | Higher material costs |

| Threading[^6] | Low-pressure systems | Limited to smaller sizes |

Threading

Threading[^6] is commonly used for small pipes. It involves screwing pipes together, ensuring a secure fit for low-pressure systems.

How is stainless steel piping usually joined?

Choosing the right joining method[^7] can prevent issues later. Learn how to match your needs with the correct technique.

Stainless steel piping[^8] is joined through welding for durability, or mechanical methods for adjustability, based on the use case.

Advantages and Challenges of Common Techniques

Large Diameter Stainless Steel Tubes

Large pipes[^9] often require welding due to their size and pressure needs. However, mechanical fittings are sometimes used for quick installation.

Regional Standards

Different regions[^10] prefer specific sizes and methods. For example, in the UK, threaded joints are common for smaller applications.

How to join a stainless steel water pipe?

Joining stainless steel water pipes[^11] incorrectly can lead to leaks. Follow best practices for water systems.

For water pipes, common methods include welding for permanence and mechanical fittings for ease of maintenance.

Tips for Joining Stainless Steel Water Pipes

Selecting the Right Materials

Choose corrosion-resistant materials[^12] to handle water exposure.

Testing the Joints

[Pressure tests](Pressure tests)[^13] ensure a leak-free connection. Always test before commissioning the system.

| Test Type | Purpose[^14] | Frequency |

|---|---|---|

| Hydrostatic[^15] | Ensures no leaks | Before use |

| Pneumatic[^16] | Verifies pressure tolerance | Routine checks |

How is stainless steel joined?

Stainless steel joining methods[^17] vary, but using the wrong approach can affect performance. Choose carefully.

Stainless steel[^18] is joined through welding, threading, or mechanical connections. Each method meets specific functional needs.

Welding Types for Stainless Steel

TIG Welding

Tungsten inert gas (TIG) welding[^19] provides precision and strong bonds. It's ideal for intricate projects.

MIG Welding

Metal inert gas (MIG) welding[^20] is faster, suitable for less complex applications.

| Welding Type | Features[^21] | Best Applications |

|---|---|---|

| TIG[^19] | Precision, neat finish | Industrial, decorative |

| MIG[^20] | Faster, less expensive | General construction |

Conclusion

Summarizing key points:

- Stainless steel pipes[^2] can be joined by welding, threading, or mechanical fittings.

- The method depends on pipe size, application, and cost.

- Welding[^3] offers a permanent solution, while fittings are adjustable.

- Water pipes need corrosion-resistant materials[^12] and thorough testing.

- Always consult regional standards[^10] and choose the right method.

Choose the best joining method to ensure reliable performance. Stainless steel is versatile and durable when properly connected.